|

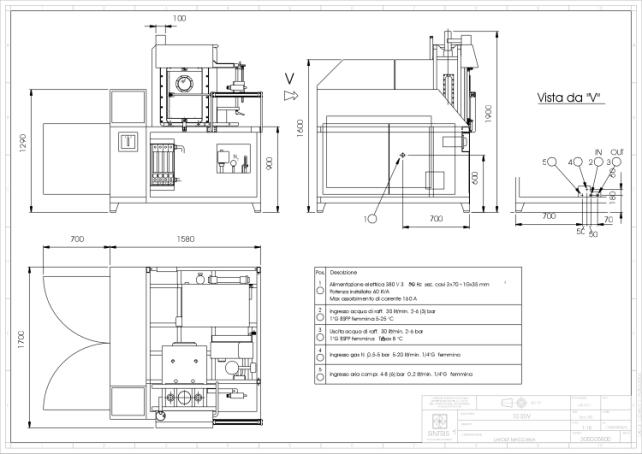

*AUTOMATIC SINTERING MACHINE mod.

10STV, WITH CONTROLLED ATMOSPHERE, 1 STATION 60Kva MONOPHASE, 26TON. |

|

|

|

|

|

Main

Features |

|

|

· Sintering machine suitable for

producing segments and small series of diamond tools. |

|

|

· Mould heating system for direct

passing of alternate current.(Joule effect) |

|

|

· Sintering with graphite moulds. |

|

|

· Sintering under controlled atmosphere by means of vacuum/inert gas

programmable wash. |

|

|

· K – type thermo-couples for operating

temperatures of up to 1000°c. |

|

|

· Cooling plates, transformer and vacuum

chamber with flow visualisation and

water temperature. |

|

|

· 60 kVA Monophase transformer, (maximum

power is limited electronically to

165A) by switch for 5 different tensions between the electrodes (maximum

power limit for heating). |

|

|

· Controller program with cycles

divisible into 12 steps. Each step includes: |

|

|

§ temperature |

|

|

§ pressure |

|

|

§ max. power limit |

|

|

§ heating time |

|

|

§ holding time |

|

|

· Compression force controlled electronically (loop system) |

|

|

· Process data visualisation (set and

real) and alarms. |

|

|

· Machine complies with EEC regulations. |

|

|

|

|

|

Options |

|

|

· Temperature control by means of

optical pyrometer 350 – 1300°C. |

|

|

· Segment height control while sintering takes place (linear

transducer on cylinder, resolution of 0,01mm) |

|

|

· Data acquisition system on external PC. |

|

|

· Regenerative system for the reduction

of minimum compression force (from 1700 to 700kg). |

|

|

· Electrodes in graphite and amorphous carbon. |

|

|

· Aluminium frames. |

|

|

· Graphite plates. |

|

|

· Graphite moulds. |

|

|

· Prearrangement for modem installation

for remote assistance. |

|

|

|

|

|

Technical data |

|

|

· Max. sintering area |

60 cm2 (850°C; 350kg/cm2) |

|

· Power supply |

380 / 400V 3phs 50Hz |

|

· Max. power consumption |

60 kVA (165 A) |

|

· Transformer |

60 kVA |

|

· Compression force (adjustable) |

1700 - 26000 kg |

|

· Electrode dimensions |

140 x 140x60(h)mm |

|

· Plate dimensions |

250 x 250x60(h)mm |

|

· Aluminium frames dimensions |

168 x 148mm |

|

· Max. mould height |

135mm |

|

· Controller |

PLC Siemens S5 |

|

· Gas consumption |

5 – 20 l/min N2/Ar2 (max. 5% H2) |

|

· Air consumption (filtered) |

2 l/min 6 bar |

|

· Industrial water consumption |

40 - 50 l/min 2–6 bar |

|

· Colour |

Choice |

|

· Overall size (approx.) |

1700x1700x2100(h) mm |

|

· Weight (approx.) |

2000 kg |