|

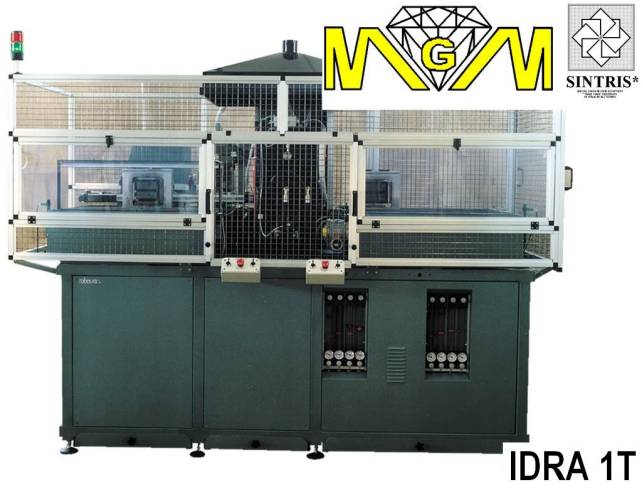

*AUTOMATIC SINTERING MACHINE mod.

IDRA 1T, WITH ONE STATION, 120 kVA,

42TON. |

|

|

|

|

|

Main

features |

|

|

· Machine suitable for the continuous

production of average/large series of diamond segments. |

|

|

· The sintering process takes place in a controlled

atmosphere in the sintering stations

by inlet of inert/reducing gas in the sintering station. |

|

|

· Temperature control with thermo-couple

automatically inserted in the center of the mould. |

|

|

· Type K thermo-couple for operating

temperatures up to 1000°C. |

|

|

· Evacuation system and smoke filtering

with water filter. |

|

|

· Control program with cycles divided

into 12 steps. Each step includes: |

|

|

§ temperature |

|

|

§ pressure |

|

|

§ max. power limit |

|

|

§ heating time |

|

|

§ holding time |

|

|

· Memory allows for storing of up to 120

sintering programs. |

|

|

· 18 mould unloading and loading

magazine. |

|

|

· Automatic mould feeding from mould

magazine. |

|

|

· 18 special aluminium frames. |

|

|

· process data visualisation (set and

real) and alarms. |

|

|

|

|

|

Options |

|

|

· Analogic outlet for variable process

recording. |

|

|

· Pyrometer 350-1300°C to be used

alternatively to the thermo-couple. |

|

|

· Height segment reading during sintering

process (linear transducer on cylinder, resolution of 0.01 mm) with possible

cycle interruption according to feedback. The system allows for pressure

control during the liquid phase of

sintering. |

|

|

· Data acquisition system on external

PC. |

|

|

· Barcode reading system for automatic

selection of sintering cycle according to product in aluminium frame,

including labelling machine. |

|

|

· 36 moulds loading/unloading magazine. |

|

|

· Aluminium frames. |

|

|

· Electrodes in graphite. |

|

|

· Graphite plates. |

|

|

· Graphite moulds. |

|

|

· Thermo-couples. |

|

|

· Prearrangement for modem installation

for remote assistance. |

|

|

|

|

|

Technical Data |

|

|

· Max. sintering area |

110 cm2

(850°C 350kg/cm2) |

|

· Approx. sintering cycle time |

11 - 12 min. |

|

· Productivity |

400-450 segm/h

(40x2.8mm -90segm/mould) |

|

|

200-220 segm/h

(24x10mm - 44segm/mould) |

|

· Loading and unloading magazine |

n.18 moulds |

|

· Power supply |

380 / 400V 3phs 50Hz |

|

· Max. power consumption |

120 kVA (175 A) |

|

· Transformer |

120 kVA |

|

· Compression force (adjustable) |

3000 - 42000 kg |

|

· Electrode dimensions |

150 x 160x60(h)mm |

|

· Plate dimensions |

150 x 160x65(h)mm |

|

· Aluminium frames dimensions |

193 x 158mm |

|

· Max. mould height |

110mm |

|

· Gas consumption |

10 – 20 l/min N2/Ar2 (max. 5% H2) |

|

· Air consumption (filtered) |

10 l/min 6 bar |

|

· Industrial water consumption |

60-80 l/min 2–6 bar

10-20°C |

|

· Colour |

Choice |

|

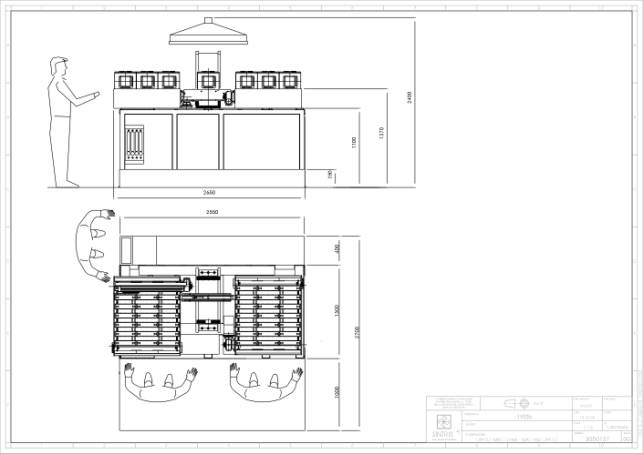

· Overall size (approx.) |

2700x2000x2500(h)

mm |

|

· Weight (approx.) |

3000 kg |