|

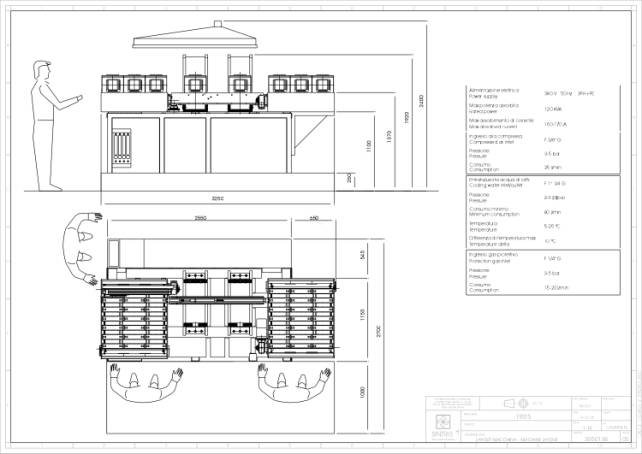

*AUTOMATIC SINTERING MACHINE mod.

IDRA 2T, WITH TWO STATIONS, 120 kVA,

42TON. |

|

|

|

|

|

Main

features |

|

|

· Machine suitable for the continuous

production of average/large series of diamond segments. |

|

|

· The sintering process takes place in a controlled

atmosphere in the 2 stations by inlet

of inert/reducing gas. During the transport between the sintering to the

cooling stations the mould is protected by a “shower” of the same gas. |

|

|

· Temperature control with thermo-couple

automatically inserted in the center of the mould. |

|

|

· Type K thermo-couple for operating

temperatures up to 1000°C. |

|

|

· Evacuation system and smoke filtering

with water filter. |

|

|

· Sintering and cooling times are the

same. |

|

|

· Control program with cycles divided

into 12 steps. Each step includes: |

|

|

§ temperature |

|

|

§ pressure |

|

|

§ max. power limit |

|

|

§ heating time |

|

|

§ holding time |

|

|

· Memory allows for storing of up to 120

sintering programs. |

|

|

· 18 mould unloading and loading

magazine. |

|

|

· Automatic mould feeding from mould

magazine. |

|

|

· 18 special aluminium frames. |

|

|

· process data visualisation (set and

real) and alarms. |

|

|

· Machine complies with CE regulations. |

|

|

|

|

Options

|

|

|

· Analogic outlet for variable process

recording. |

|

|

· Pyrometer 350-1300°C to be used

alternatively to the thermo-couple. |

|

|

· Height segment reading during

sintering process (linear transducer on cylinder, resolution of 0.01 mm). |

|

|

· Data acquisition system on external

PC. |

|

|

· Barcode reading system for automatic

selection of sintering cycle according to product in aluminium frame,

including labelling machine. |

|

|

· 36 moulds loading/unloading magazine. |

|

|

· Aluminium frames. |

|

|

· Thermo-couples. |

|

|

· Electrodes in graphite. |

|

|

· Graphite plates. |

|

|

· Graphite moulds. |

|

|

· Thermo-couples. |

|

|

· Prearrangement for modem installation

for remote assistance. |

|

|

|

|

|

Technical Data |

|

|

· Max. sintering area |

110 cm2

(850°C 350kg/cm2) |

|

· Approx. sintering cycle time |

9 min. |

|

· Productivity |

500-550 segm/h

(40x2.8mm -90segm/mould) |

|

|

250-280 segm/h

(24x10mm - 44segm/mould) |

|

· Loading and unloading magazine |

n.18 moulds |

|

· Power supply |

380 / 400V 3phs 50Hz |

|

· Max. power consumption |

120 kVA (175 A) |

|

· Transformer |

120 kVA |

|

· Compression force on the 2 stations

(adjustable) |

3000 - 42000 kg |

|

· Electrode dimensions |

150 x 160x60(h)mm |

|

· Plate dimensions |

150 x 160x65(h)mm |

|

· Aluminium frames dimensions |

193 x 158mm |

|

· Max. mould height |

110mm |

|

· Gas consumption |

15 – 25 l/min N2/Ar2 (max. 5% H2) |

|

· Air consumption (filtered) |

10 l/min 6 bar |

|

· Industrial water consumption |

80-100 l/min 2–6 bar

10-20°C |

|

· Colour |

Choice |

|

· Overall size (approx.) |

2000x3250x2500(h)

mm |

|

· Weight (approx.) |

3500 kg |